Preventative Maintenance Saves Lives

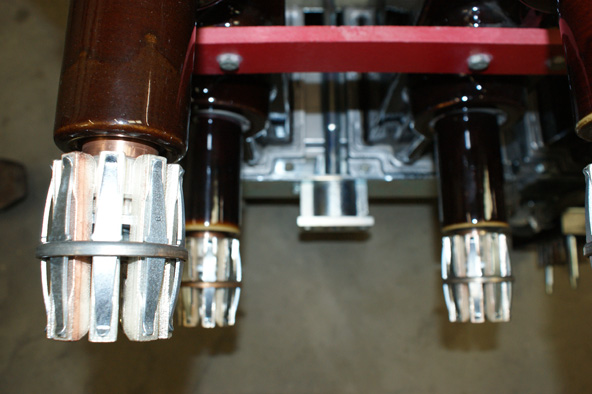

We all know that every plant requires preventative maintenance to stay healthy and productive, but how often do you test and clean your overcurrent protective devices? Outdated and neglected overcurrent devices can adversely affect results of an arc flash study. Electrical equipment that is “out of sight, out of mind” is often unattended for long periods, which could result in catastrophic failures. Preventative maintenance is important to maintain a healthy and productive plant and is critical in the protection of personnel and equipment.

We all know that every plant requires preventative maintenance to stay healthy and productive, but how often do you test and clean your overcurrent protective devices? Outdated and neglected overcurrent devices can adversely affect results of an arc flash study. Electrical equipment that is “out of sight, out of mind” is often unattended for long periods, which could result in catastrophic failures. Preventative maintenance is important to maintain a healthy and productive plant and is critical in the protection of personnel and equipment.

Consider this; the IEEE paper Protective Devices Maintenance as it Applies to the Arc Flash Hazard states “several studies have shown that low-voltage power circuit breakers which are not maintained within a 5 year period, have an average of 50% failure rate.” The same document goes on to state “industry standards for, as well as manufacturers of, low-voltage power circuits recommend a general inspection and lubrication after a specified number of operations or at least once per year, whichever comes first.”

Section 130.5 of the 2012 edition of NFPA 70E Handbook for Electrical Safety in the Workplace states “the arc flash hazard analysis must also take in to consideration the design of the overcurrent protective device and its opening time, including its condition of maintenance.”

inoLECT’s Field Service Engineers and Technicians are trained and ready to ensure your protective devices operate correctly. Call us today to schedule your over-current protective device maintenance.