Do you rack the ITE HK?

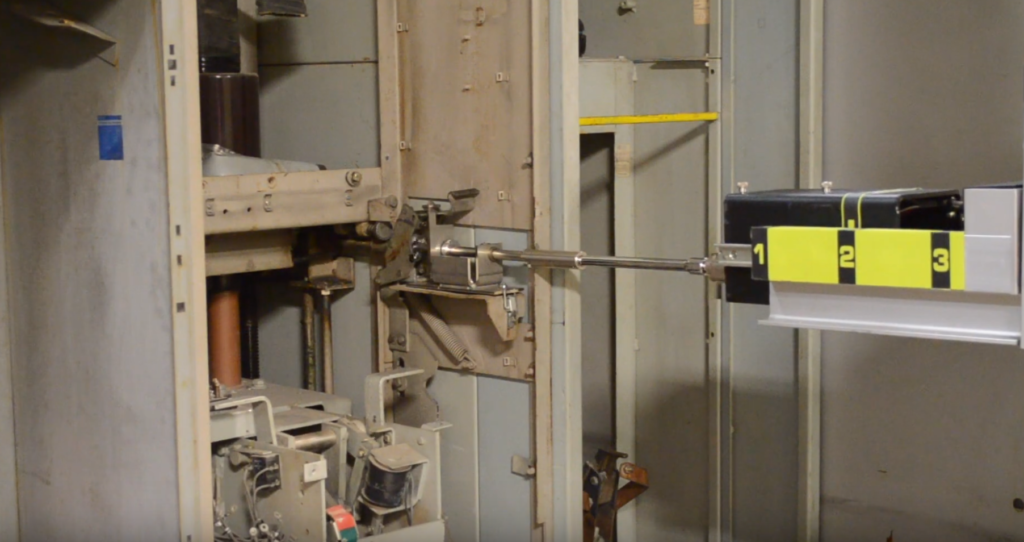

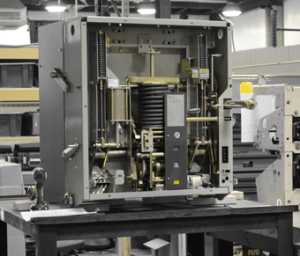

The ITE HK circuit breakers are among the most commonly used in industrial facilities and we’ve got the answer when it comes to Remote Racking. Join us for a webinar session highlighting the differences between the older breaker accessory and the latest one. Chris will demonstrate how easily the accessory is installed and used on the inoRAC3 Remote Racking devices. Register for FREE here: https://us02web.zoom.us/webinar/register/WN_32v-tarGTOaEG9s49JyZjQ

The ITE HK circuit breakers are among the most commonly used in industrial facilities and we’ve got the answer when it comes to Remote Racking. Join us for a webinar session highlighting the differences between the older breaker accessory and the latest one. Chris will demonstrate how easily the accessory is installed and used on the inoRAC3 Remote Racking devices. Register for FREE here: https://us02web.zoom.us/webinar/register/WN_32v-tarGTOaEG9s49JyZjQ

We are so proud to introduce the newest edition to our global sales team – Pacific Power Reps! With over 10 years of successful industrial and electrical equipment sales experience, multi-state coverage and a winning attitude, founder Greg Albertyn and his team are excited to hit the ground running for inoLECT. Check out their website for more information:

We are so proud to introduce the newest edition to our global sales team – Pacific Power Reps! With over 10 years of successful industrial and electrical equipment sales experience, multi-state coverage and a winning attitude, founder Greg Albertyn and his team are excited to hit the ground running for inoLECT. Check out their website for more information:

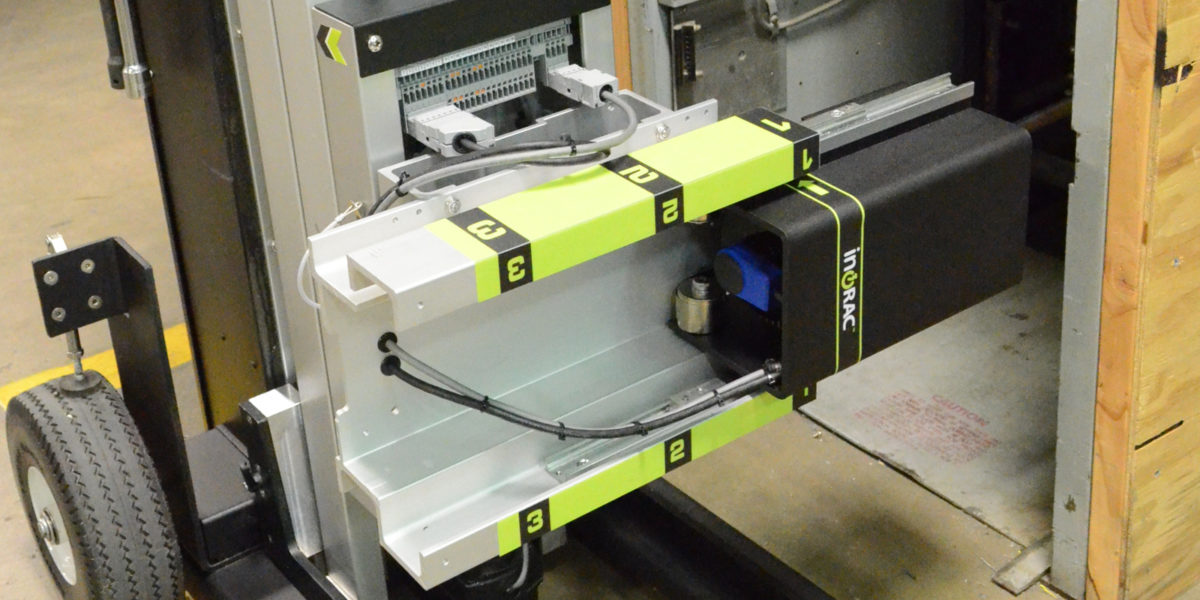

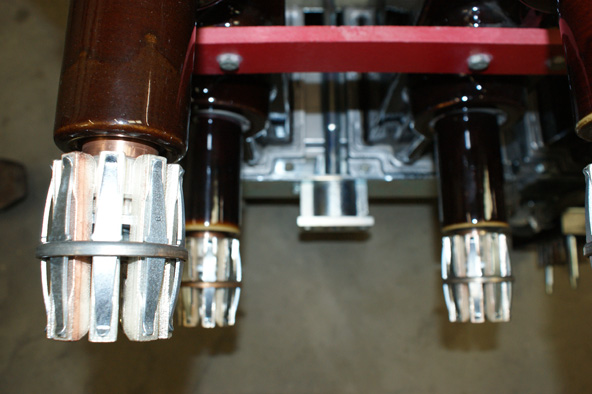

inoLECT is proud to announce their latest product in the inoRAC Remote Racking line – the i90. This lightweight, easily installed accessory allows the Remote Racking unit to connect and disconnect a contactor to an energized bus remotely, from outside of the Arc Flash boundary. The process of ‘throwing’ these switch-style levers involves serious hazards, similar to that of racking circuit breakers. Operators are at risk of severe injury or death. Utilizing the i90 device with the advanced technology of an inoRAC, eliminates these risks for personnel and provides optimal equipment protection. No switchgear modifications are required and users can quickly install, use and uninstall the accessory to move to the next breaker or motor starter. Multiple versions are available for compatibility across most major manufacturers medium voltage contactors and other electrical equipment. Call 1-844-inoLECT for a free onsite demonstration or visit

inoLECT is proud to announce their latest product in the inoRAC Remote Racking line – the i90. This lightweight, easily installed accessory allows the Remote Racking unit to connect and disconnect a contactor to an energized bus remotely, from outside of the Arc Flash boundary. The process of ‘throwing’ these switch-style levers involves serious hazards, similar to that of racking circuit breakers. Operators are at risk of severe injury or death. Utilizing the i90 device with the advanced technology of an inoRAC, eliminates these risks for personnel and provides optimal equipment protection. No switchgear modifications are required and users can quickly install, use and uninstall the accessory to move to the next breaker or motor starter. Multiple versions are available for compatibility across most major manufacturers medium voltage contactors and other electrical equipment. Call 1-844-inoLECT for a free onsite demonstration or visit

Schedule a free demo by calling 1-844-inoLECT or

Schedule a free demo by calling 1-844-inoLECT or  As you probably know, the OSHA Revised §1910.269 and Subpart V compliance deadline for provisions on fall protection, minimum approach distances, and arc-flash protection is April 1, 2015. The employer must determine the maximum anticipated per-unit transient overvoltage, phase-to-ground, through an engineering analysis no later than this date, for voltages over 72.5 kilovolts. For more information about why OSHA revised its ruling and how you can prepare,

As you probably know, the OSHA Revised §1910.269 and Subpart V compliance deadline for provisions on fall protection, minimum approach distances, and arc-flash protection is April 1, 2015. The employer must determine the maximum anticipated per-unit transient overvoltage, phase-to-ground, through an engineering analysis no later than this date, for voltages over 72.5 kilovolts. For more information about why OSHA revised its ruling and how you can prepare,

Arc Flash Remediation is the process of developing a plan to correct deficiencies within your electrical system. We’ll be hosting seminars in the upcoming months, in different areas of our customer base, to touch on the importance of Remediation planning. We’ll discuss solutions for optimum system performance, for whatever plant size, budget and time constraints you may have. Learn more about the steps you can take to move towards a safe and reliable system.

Arc Flash Remediation is the process of developing a plan to correct deficiencies within your electrical system. We’ll be hosting seminars in the upcoming months, in different areas of our customer base, to touch on the importance of Remediation planning. We’ll discuss solutions for optimum system performance, for whatever plant size, budget and time constraints you may have. Learn more about the steps you can take to move towards a safe and reliable system.  inoLECT is an authorized reseller of Siemens MV Vacuum Roll-in Replacement Breakers. Replacing breakers increases the reliability, safety and performance of your site, while reducing operating and maintenance costs. Siemens offers the best Vacuum Circuit Breaker in the industry, and when paired with a Remote Racking unit, can eliminate the risk of Arc Flash hazards. Regardless of the type of current breakers you have onsite, we will assist you in finding the replacement which best meets your needs. Contact us today for details or a price quote.

inoLECT is an authorized reseller of Siemens MV Vacuum Roll-in Replacement Breakers. Replacing breakers increases the reliability, safety and performance of your site, while reducing operating and maintenance costs. Siemens offers the best Vacuum Circuit Breaker in the industry, and when paired with a Remote Racking unit, can eliminate the risk of Arc Flash hazards. Regardless of the type of current breakers you have onsite, we will assist you in finding the replacement which best meets your needs. Contact us today for details or a price quote.

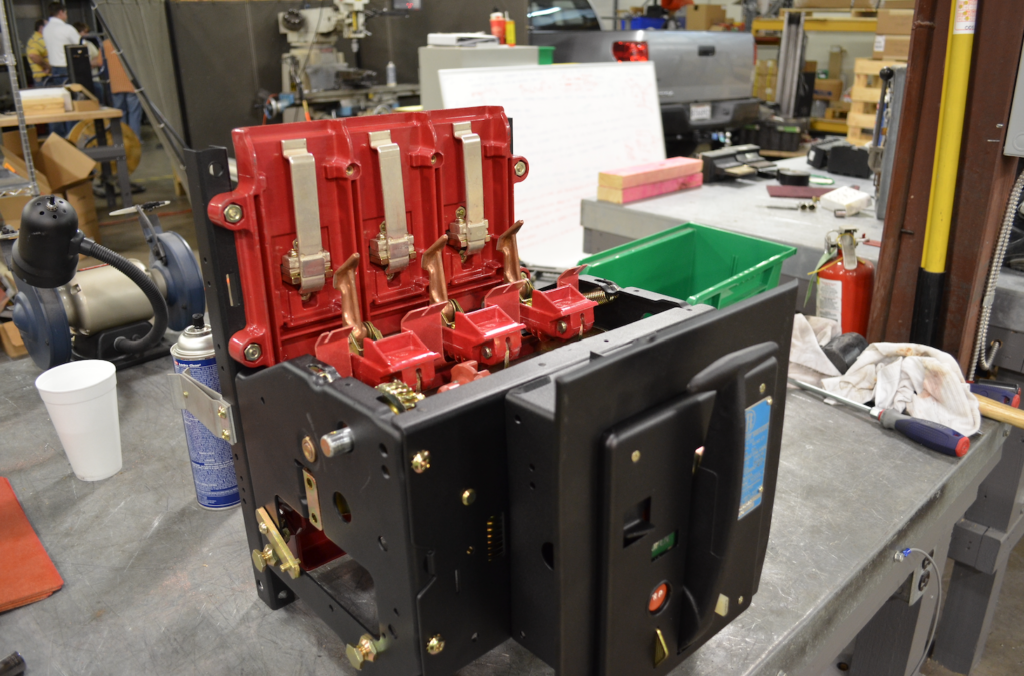

We all know that every plant requires preventative maintenance to stay healthy and productive, but how often do you test and clean your overcurrent protective devices? Outdated and neglected overcurrent devices can adversely affect results of an arc flash study. Electrical equipment that is “out of sight, out of mind” is often unattended for long periods, which could result in catastrophic failures. Preventative maintenance is important to maintain a healthy and productive plant and is critical in the protection of personnel and equipment.

We all know that every plant requires preventative maintenance to stay healthy and productive, but how often do you test and clean your overcurrent protective devices? Outdated and neglected overcurrent devices can adversely affect results of an arc flash study. Electrical equipment that is “out of sight, out of mind” is often unattended for long periods, which could result in catastrophic failures. Preventative maintenance is important to maintain a healthy and productive plant and is critical in the protection of personnel and equipment. Each June, the United States National Safety Council encourages organizations to get involved and participate in

Each June, the United States National Safety Council encourages organizations to get involved and participate in