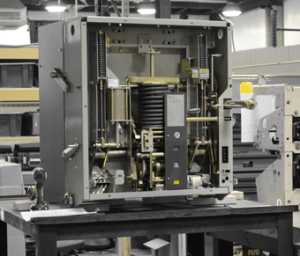

New Product Release: Westinghouse DB-50 & DB-25 Racking Systems

inoLECT is proud to release a brand new Remote Racking system for Westinghouse DB-50 and DB-25 circuit breakers. This all-in-one racking system is easily installed and operated just like the full inoRAC2 Remote Racking unit. The device constantly monitors torque and breakers position throughout the entire racking process, allowing a more precise operation that will protect against equipment damage. Operators perform functions from over 75 feet away, using a Portable Touch Panel which features a high-definition color touchscreen. Step-by-step instructions allow ease of use for personnel.

The U.S. Department of Labor estimates that more than 400 fatalities and nearly 10,000 serious injuries occur each year due to Arc Flash related incidents, with industry experts estimating even higher numbers. These frightening statistics equate to an Arc Flash related incident occurring up to 10 times a day and at least one worker losing their life, every day in the U.S. Don’t let your employee be the next victim. Click here for more information and to request a quote on this life-saving product.

01

Arc Flash Remediation is the process of developing a plan to correct deficiencies within your electrical system. We’ll be hosting seminars in the upcoming months, in different areas of our customer base, to touch on the importance of Remediation planning. We’ll discuss solutions for optimum system performance, for whatever plant size, budget and time constraints you may have. Learn more about the steps you can take to move towards a safe and reliable system.

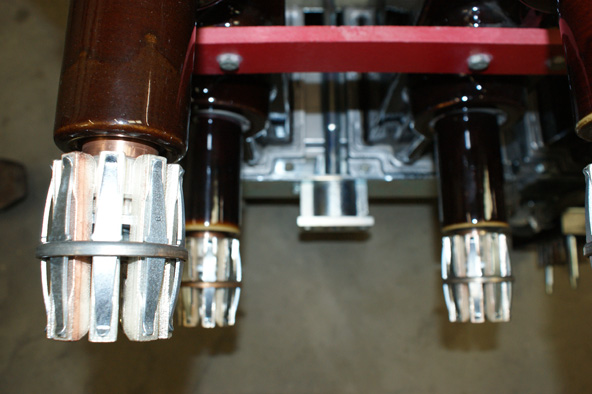

Arc Flash Remediation is the process of developing a plan to correct deficiencies within your electrical system. We’ll be hosting seminars in the upcoming months, in different areas of our customer base, to touch on the importance of Remediation planning. We’ll discuss solutions for optimum system performance, for whatever plant size, budget and time constraints you may have. Learn more about the steps you can take to move towards a safe and reliable system.  inoLECT is an authorized reseller of Siemens MV Vacuum Roll-in Replacement Breakers. Replacing breakers increases the reliability, safety and performance of your site, while reducing operating and maintenance costs. Siemens offers the best Vacuum Circuit Breaker in the industry, and when paired with a Remote Racking unit, can eliminate the risk of Arc Flash hazards. Regardless of the type of current breakers you have onsite, we will assist you in finding the replacement which best meets your needs. Contact us today for details or a price quote.

inoLECT is an authorized reseller of Siemens MV Vacuum Roll-in Replacement Breakers. Replacing breakers increases the reliability, safety and performance of your site, while reducing operating and maintenance costs. Siemens offers the best Vacuum Circuit Breaker in the industry, and when paired with a Remote Racking unit, can eliminate the risk of Arc Flash hazards. Regardless of the type of current breakers you have onsite, we will assist you in finding the replacement which best meets your needs. Contact us today for details or a price quote.

We all know that every plant requires preventative maintenance to stay healthy and productive, but how often do you test and clean your overcurrent protective devices? Outdated and neglected overcurrent devices can adversely affect results of an arc flash study. Electrical equipment that is “out of sight, out of mind” is often unattended for long periods, which could result in catastrophic failures. Preventative maintenance is important to maintain a healthy and productive plant and is critical in the protection of personnel and equipment.

We all know that every plant requires preventative maintenance to stay healthy and productive, but how often do you test and clean your overcurrent protective devices? Outdated and neglected overcurrent devices can adversely affect results of an arc flash study. Electrical equipment that is “out of sight, out of mind” is often unattended for long periods, which could result in catastrophic failures. Preventative maintenance is important to maintain a healthy and productive plant and is critical in the protection of personnel and equipment.